Advantages

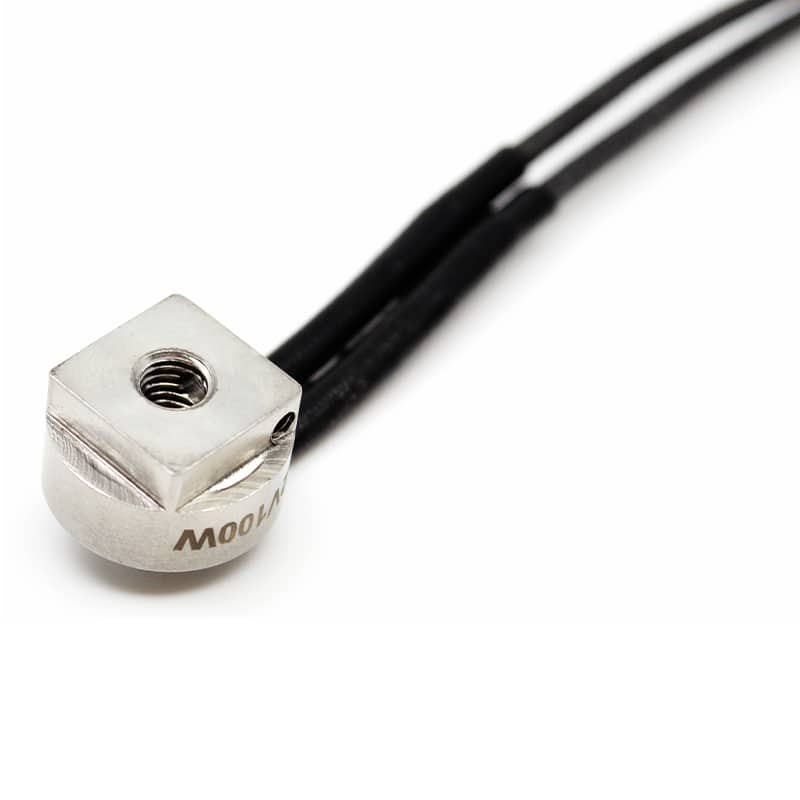

- 360° uniform heating: Extruder can be heated averagely on a 360°base.

- A maximum wattage to 150W can be achieved, when the heater’s volume and surface tripled in a ring shape (comparing with cartridge shape). Higher wattage also can be reached by special work craft.

- The volume of the heater is larger (about 3 times larger than the conventional heaters); the increased heat dissipation area means that the power of the heater can be increased by more than 3 times compared with the conventional heater, and the maximum power can be produced to 150w; if a special process is used to process the heater, the device can achieve more power and can meet a wider range of requirements.

- Meanwhile the ring heater’s service life will be 3 times longer as the power density goes down. As the power density is reduced, the service life will be increased by about 3 times larger than the life of conventional electric heater cartridge.

- The maximum working temperature for a ring heater can reach 600℃ to 900℃ depending on different work craft. In general, the ring element allows the operating temperature to reach 600℃. The specially processed ring heaters can operate up to 900℃.